Professionelle

Laserbeschriftungssysteme

für die Industrie

für die Industrie

SHT steht für Software, Hardware und Technik. Gewachsen aus diesen drei Komponenten und jahrzehntelanger Erfahrung bieten wir Ihnen hochwertige und zuverlässige industrielle Laserbeschriftungssysteme. Überzeugend in Qualität, Präzision und Flexibilität.

Zuverlässige

Laserbeschriftungssysteme

für Ihren Bedarf

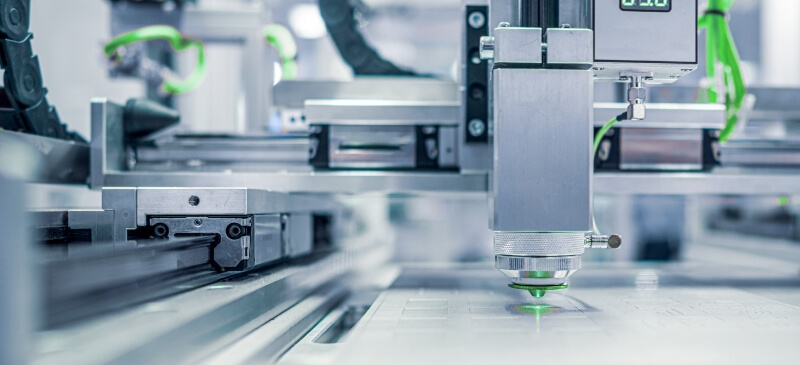

Unsere Kernkompetenz liegt in der Entwicklung und Herstellung hochwertiger Lasersysteme für den industriellen Produktionsbereich. Ob es sich um ein Beschriftungssystem für eine Kleinserie oder eine Anlage für die Serienproduktion handelt – wir finden stets eine, auf Ihren speziellen Bedarf abgestimmte, Lösung.

Unsere benutzerfreundliche Beschriftungs- und Anwendungssoftware sowie unsere fachkompetente Beratung runden das Komplettpaket ab.

SHT – diese Buchstabenkombination steht für unsere Kernkompetenzen: Software, Hardware und Technik.

Seit Jahrzehnten setzen wir in der Laserbeschriftung auf unsere eigene, sorgfältig durchdachte SOFTWARE. Ihr Vorteil ist, dass der Editor auch ohne das Laserprogramm genutzt werden kann. Dadurch können Beschriftungsbilder nicht nur auf dem Laser, sondern auch auf einem normalen Computer erstellt werden, ganz gleich wo er sich befindet. Diese Flexibilität erhöht den Komfort und erleichtert den Ablauf Ihres Prozesses.

Unsere Mitarbeiter planen und realisieren eine HARDWARE, die speziell auf Ihre Prozesse zugeschnitten ist. Alternativ bieten wir Ihnen bewährte, standardisierte Lösungen, um Ihre gewünschten Beschriftungsergebnisse zu erzielen. Dabei setzen wir auf qualitativ hochwertige und verlässliche Markierungssysteme mit Komponenten, die von den aktuellen Marktführern stammen.

Unser Fokus liegt auf der TECHNIK und den entsprechenden Lösungen. Unsere Ingenieure und Techniker arbeiten mit Ihnen und Ihren Projektverantwortlichen an Konzepten, die wir in Zusammenarbeit mit unseren Partnern realisieren. Auch nach Abschluss des Projekts stehen wir Ihnen mit Rat und Tat zur Seite.

Mit unserer jahrzehntelangen Erfahrung im Bereich der industriellen Lasermarkierung bieten wir Ihnen hochwertige Produkte „Made in Germany“. Überzeugend in Qualität, Präzision und Flexibilität.

- Laserbeschriftungssysteme (auch als OEM-Version erhältlich)

- Standardbeschriftungsanlagen

- Sonderanlagen (bei Bedarf mit kundenspezifischer Software)

- Datenbankanbindung und Vision Systeme

- Eigene Beschriftungssoftware BLS-WIN

Über 35 Jahre Erfahrung

auf dem Gebiet der Laserbeschriftung

Vernetzte Technologien

für die Industrie 4.0

Flexible Lösungen

von Plug-and-Play bis zur Sonderfertigung

Zertifiziertes Qualitätsmanagement

System nach ISO 9001

Individuell anpassbare

Software

Kostenlose Beratung

und Musterbeschriftung

Erfolg durch

Know-how und Erfahrung

Mit über 35 Jahren Erfahrung in der Branche verfügen wir über ein großes Know-how, von dem unsere Kundinnen und Kunden weltweit profitieren. Für einen gleichbleibend hohen Qualitätsstandard unterliegt unser kompletter Fertigungsprozess der ISO 9001.

Ganz im Sinne unserer Firmenphilosophie rücken wir Qualität und Kundenzufriedenheit in den Mittelpunkt. So stehen wir Ihnen auch nach der Lieferung Ihres Lasersystems jederzeit mit unseren qualifizierten Mitarbeitern zur Verfügung, so dass Sie über Jahre reibungslos produzieren können.

Ihr aktuelles Projekt fordert die Integration eines Beschriftungslasers?

Gravieren, Abtragen, Anlassen – welchen Beschriftungslaser und welche Methode Sie verwenden, entscheidet über das Resultat. Wir fertigen Beschriftungslaser ebenso wie Spezialanlagen – nehmen Sie einfach Kontakt mit uns auf. Wir beraten Sie gerne!

Wir begleiten Sie vom Erstgespräch bis zur Integration in die Fertigungslinie

Vom ersten Beratungsgespräch bis zur detailgenauen Umsetzung: Unsere Mitarbeiter haben für Ihre Anliegen und Projekte stets ein offenes Ohr. Zunächst klären wir gemeinsam, welche Anforderungen an die Hardware und Software bestehen und suchen dann nach einer für Sie optimalen Lösung.

Unsere fachkompetenten und erfahrenen Ansprechpartner beraten Sie dabei ausführlich. Für optimale Ergebnisse stellen wir Ihnen während der gesamten Entwicklung und Umsetzung einen festen Ansprechpartner bereit, der mit Ihrem Projekt bestens vertraut ist.

Anwendungen

Branchen

Die Lasertechnik eignet sich für die Bearbeitung unterschiedlichster Materialien, wie beispielsweise Metall oder Kunststoff und wird in den verschiedensten Industriezweigen genutzt. Unter Berücksichtigung ökonomischer und ökologischer Aspekte unterstützen wir Sie bei der Umsetzung branchenspezifischer Projekte mit konstanter Prozesssicherheit und gleichzeitig hoher Produktivität der Laseranlagen.

Einsatzgebiete

Das wichtigste Kriterium zur Auswahl des geeigneten Lasersystems stellen die Werkstoffe dar, die bearbeitet werden sollen. Für ein optimales Beschriftungsergebnis auf Ihren Bauteilen sind die passende Wellenlänge, geeignete Laserparameter und die richtige Laseroptik ausschlaggebend. Profitieren Sie hier von unseren technisch aktuellen Lasersystemen und unserer jahrzehntelangen Erfahrung.

Metalle, Kunststoffe, Folien, Papier, Glas, Holz oder Kabel: Sie haben einen speziellen Bedarf an Laserbeschriftungssystemen und Lasermarkiersystemen. Als einzelne Beschriftungslaser oder als komplette Markierungssysteme. Wir liefern Ihnen für Ihre Produkte die passende industrielle Lösung.

Das aus Nürnberg stammende Unternehmen SHT steht für Software, Hardware, Technik. Wir bieten Lasersysteme für die Industrie, die einfach in der Bedienung sind und nach der europäischen Maschinenrichtlinie von unseren qualifizierten Mitarbeitern entwickelt wurden und somit bei Ihnen im Unternehmen sicher verwendet werden können. Deshalb liefern wir Standardvarianten oder individuell auf Ihr Unternehmen abgestimmte Komplettlösungen – vom Beschriftungssystem für Kleinserien bis hin zu Anlagen für die Serienproduktion.

Unsere hochwertigen Produkte ergänzen wir durch eine langfristige partnerschaftliche Zusammenarbeit. So stehen Ihnen unsere Fachkräfte stets zur Verfügung, wenn Sie eine Frage oder ein Anliegen haben. Auf Wunsch erhalten Sie von uns eine kostenlose Musterbeschriftung Ihrer Materialen / Bauteile. Gerne beraten wir Sie auch über ein für Sie passendes Softwarepaket, welches auf Ihre unternehmensinternen Bedürfnisse abgestimmt wird.

Sie haben Fragen oder möchten Ihr Projekt mit uns besprechen? Nehmen Sie einfach Kontakt mit uns auf!